RC51 ROAD COMFORT RC-BARS - INSTALLATION GUIDE

Thank you for your purchase of RC-Bars. The higher and

slightly wider positioning will

enable you to take your RC51 on longer rides. They also

have the following

advantages over Heli-Bars for the RC51 that were discontinued years ago:

- Higher strength 4130 Cr-Mo steel construction instead

of mild steel.

- Clamp bushings are TIG welded to sleeves instead of

brazed.

- All TIG Welding done with ER80S-D2 rod used on race car

frames and airplane fuselages.

- Pinch bolts are stainless steel M6 x 1.0 x 25mm instead

of zinc plated steel.

- Satin black powdercoating instead of gloss black.

- Step-by-step detailed installation instructions with

high

resolution pictures.

|

PLEASE READ THIS CAUTION PARAGRAPH - IT IS

IMPORTANT:

I cannot assume liability for injury or

loss of property from your installation or use of RC-Bars. You are responsible

for ensuring that your motorcycle is safe to operate each time before you ride

it. After installation of RC-Bars it is your responsibility to make sure they

are installed properly and safe to ride with. RC-Bars were not designed for

"stunt" riding and any such use is at your own risk. It is extremely

important that you properly torque the pinch bolts to 96 in-lbs.

Over-tightening can possibly result in hardware failure and under-tightening

can possibly result in loose handlebars. Use of Torque-Seal or dabs of paint

on the pinch bolts after installation is a good way to ensure they have not

loosened over time. Otherwise you should periodically check security of the

pinch bolts. Using Loc-Tite is not recommended because a tiny amount of anti-sieze

has been applied to the pinch bolt threads to prevent corrosion. You must

ensure that unrestricted lock-to-lock steering is available without

interference from any cable, hoses, bodywork or the fuel tank. If RC-Bars are

subjected to abnormally high forces such as a tip-over, crash or collision, it

is your responsibility to inspect and determine any damage to them and make a

decision if they are still safe to use. If the bars are bent, have any cracks,

tears or deep gouges in the metal, you should consider them unsafe and not use

them further. If you use the handlebars as a tie-down point keep in mind that

it is possible the bars may rotate on the fork tubes if subjected to

abnormally high forces. Thus it would always be prudent to use secondary

tie-downs on other parts of the motorcycle. Check alignment of the RC-Bars

afterwards and reposition them if needed. When you first ride with RC-Bars,

keep in mind that at full lock steering, your inside thumb will not have as

much clearance between the grip and the fuel tank as it did before. To avoid

low speed crashes when doing u-turns or maneuvering in parking lots, you

should anticipate this. Sit on the bike with your normal riding gloves on and

explore the maximum steering limits back and forth with your hands on the bars

until you develop a method of holding the inside bar that allows full lock

steering in both directions. If your bars are positioned correctly, sliding

your inside hand outboard on the grip, or moving your thumb from under the

grip to on top of the grip is usually all that is needed. By practicing in

advance you can hopefully avoid the pain of your thumb acting as the steering

lock. If you disagree with anything in this paragraph, do not install the

RC-Bars and instead return them to me for full refund.

|

RETURN POLICY:

If you install RC-Bars and discover you are dissatisfied after riding with

them, you can return them to me within 30 days, and I will refund your $220, assuming they are only scratched from

installation/use, not damaged otherwise. You pay

for return shipping though. I

specifically know that each set of bars has been inspected thoroughly thru the

manufacturing process and each bar has been fit tested on my personal bike.

Provided they are not damaged during shipment to you, there is zero chance of

you receiving a defective part. If you experience shipping damage contact me

and I'll do a full refund.

INSTALLATION OF RC-BARS

Installation Goal:

- To install RC-Bars securely, ensuring no control cable or

hydraulic hose interference while steering lock to lock and with no damage to

finished surfaces of the motorcycle. Although there are many steps to this

installation, you will discover that each step is really not that difficult

and the whole installation will not take more than a few hours of your time

if you have the tools listed.

- Read through it these instructions once before you

start to get the overall

picture, then follow it step-by-step.

- Note that some installation pictures below are of the

prototype bars, yours of course will be powdercoated black and look much

nicer!

Tools Required :

- Of course you are entitled to use whatever tools and

methods you think work best, listed below is what has worked at least once!

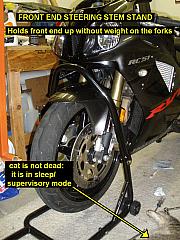

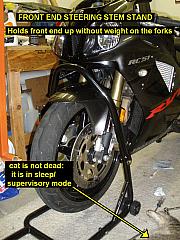

- Motorcycle stands, the best setup is a rear PitBull

type stand and the front end on a steering stem support stand. Otherwise

you'll need to figure out something to

take the weight off the forks since the top triple clamp will be removed.

- Dremel tool, hacksaw blade or other small saw blade to

cut the cast aluminum tab at the front brake line.

- Sockets: 8mm for brake and clutch controls, 12mm for

stock bars and top triple clamp pinch bolts, 5mm Allen Head for RC-Bars,

41mm

or 1-5/8" socket for the steering stem nut.

- Rubber or plastic hammer to tap on the bottom of the

top triple clamp to remove it.

- Torque Wrenches: (borrow or rent of you have to) a

large torque wrench accurate up to 101 ft·lbs for the

steering stem nut, another mid sized wrench accurate at 25ft·lbs for the fork pinch bolts and

hydraulic banjo bolts, and a small in-lbs torque wrench to put the

handlebar pinch bolts at 96 in-lbs.

- Phillips screw drivers - a shorty one for handlebar switch controls

and a regular sized one for the bar end damper weights.

- Needle nose pliers for removing the inner bar

weights.

- Air compressor with air nozzle - for removing grips

from bars.

- A few towels to protect painted surfaces from scratches

while you work.

- Vise and pliers to bend the front brake reservoir mount

bracket.

Installation Steps:

1) Put the bike up on the rear wheel stand.

2) Remove the windshield, mirrors and fairing stay from the upper fairing to give

yourself more room to work around the handlebars.

3) Put a towel or some sort of protection over the gas

tank just in case you drop the torque wrench or the socket falls off. Turn the

front wheel all the way to the left steering lock and use the 41mm

or 1-5/8" socket to loosen the steering stem

nut.

4) Straighten the front wheel and put the front end up

on the steering stem stand to take weight off the forks.

5) Put towels down on the flat fairing surface below the

clutch and front brake levers to keep the fairing from getting scratched.

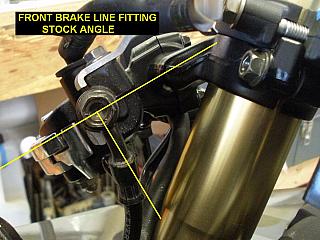

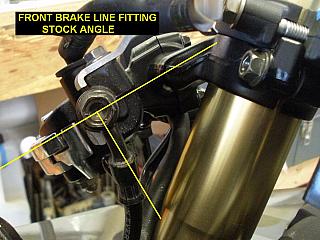

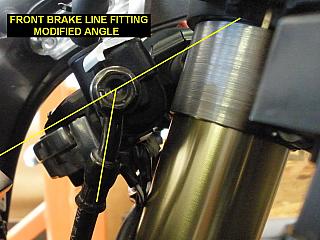

6) Modify the angle of the front brake hose fitting at the master

cylinder. It needs to be more parallel with the fork leg. If done carefully,

it can be done without fluid leaking or having to bleed the brake afterwards.

Follow this procedure:

- Use a dremel tool, hacksaw blade or other small saw blade to

cut about halfway into the cast aluminum tab on the master cylinder, then break it off by

prying between it and the banjo fitting. This tab needs to be removed so

you can rotate the brake line further than it currently allows. You may find

it easier to use the steps below to rotate the brake line away from the

tab temporarily to make it easier to cut. Be sure to remove enough of

the tab so the brake line will rotate past it.

- Put a rubber band on the brake lever to keep slight

brake pressure. This ensures that fluid comes out instead of air going into

the brake line should you mistakenly loosen the banjo fitting too far.

- Put shop towels around the area to protect the painted

surfaces just in case too. Unlike the picture above..dooh!

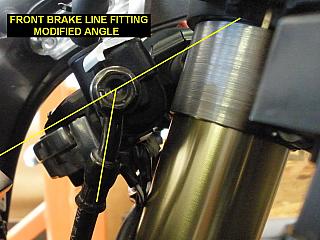

- Put a 12mm socket on a long breaker bar which gives

you precise control of the banjo bolt. Loosen the banjo bolt a tiny amount

maybe 1/8 to 1/4 of a turn at the most, just enough to allow you to rotate

the brake line fitting with some force by hand. You might find it best

to loosen the banjo a tiny amount then rotate the fitting with the banjo

as you tighten it back up. This tiny movement can be repeated until the

deired angle is acheived.

- Rotate the brake line fitting to be more parallel with

the fork leg as shown in the picture. Compare the angles shown in yellow.

- Hold the fitting in the new position while you re-torque the

banjo bolt to 25ft·lbs. Without the tang there anymore, it will want to

rotate as you tighten the banjo bolt.

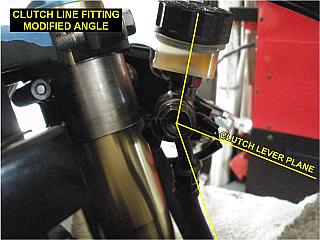

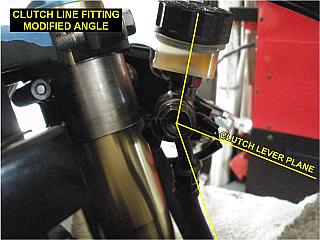

7) Modify the angle of the clutch hose fitting at the master

cylinder. It needs to be more parallel with the fork leg too. Again, If done carefully,

it can be done without fluid leaking or having to bleed the clutch afterwards.

Follow the same procedure as you did for the brake fitting except do not

remove the tang. We're rotating the fitting the other direction away from the

tang so it's not in the way.

- Adjust the clutch fitting to this angle:

- As before, hold the fitting in the new position while you re-torque the

banjo bolt to 25ft·lbs.

8) Prepare the left handlebar for removal:

- Loosen and remove the clutch lever/master cylinder

assembly and turn-signal/hi-beam switch module. Since you've protected

your fairings, they can just rest on the fairing until reinstallation.

- Use a phillips screw driver to remove

left bar

end damper weight.

- Remove the left grip, using the air nozzle just under

the rubber to pressurize it. You may have to use your hand to block off air

escape so it pumps up enough to slide off the bar.

9) Prepare the right handlebar for removal:

- Loosen and remove the front brake lever/master

cylinder assembly and kill switch module. Since you've protected your

fairings, they can just rest on the fairing until reinstallation.

- Use a phillips screw driver to remove the right bar

end damper weight.

- Remove the screws and remove the top cap from the throttle housing.

- Due to throttle cable length, you cannot remove the

throttle housing/tube assembly at this time, it will come of in a later

step. There's no need to remove the throttle grip either.

10) Put a towel over the instrument panel to protect it.

Same thing for the gas tank. Loosen the fork pinch bolts on the top triple

clamp, and remove the steering stem nut. Put some upward pressure by hand on

one side of the top triple clamp then use a rubber or plastic hammer to gently

tap upward from below on the other side to remove it. Let the triple clamp

rotate forward and rest on the towel on the instrument panel. The ignition

lock will keep you from taking it totally off the bike.

Do not use a rear wheel stand as the only method of

holding the bike while removing the steering stem, it puts excessive load on

the forks and bottom triple clamp. As mentioned before, use of a steering stem

stand or anything similar is best. Don't put blocks under the oil filter

either!

11) Loosen the clamp bolts and remove the left and right

handlebars. To remove the right bar, you'll have to slide the throttle inwards towards

the fork to find a spot that allows you to remove the bar off the fork leg, then

slide the throttle assembly off the bar. Remove the circlips off both fork legs

too, they are not used with the new RC-Bars.

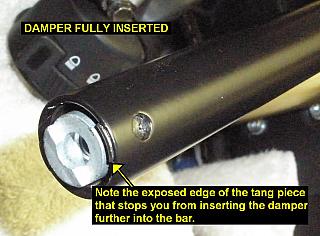

12) Remove the internal dampers from

the bars. Put each handle bar into a vise to hold it securely. Screw the bar

weight end back on to use as a handle to pull the inner weight out. Use needle

nosed pliers to push in the tangs in the holes at the end of the bar and you

apply pulling pressure on the end weight. This allows the inner weight to slide

out the of the bar. Expect to have to pull pretty hard, wiggle it around etc,

because the rubber part of the damper is probably stuck to the inner bar, plus

the tangs don't like to slide out of the tube either.

13) Install the left RC-Bar onto the fork leg and slide it

down far enough to get the trip clamp back on. Note that when installed

correctly, the handlebar tube will be

at the top of the sleeve that slides over the fork leg. If not, you have the

wrong one on and need to swap it.

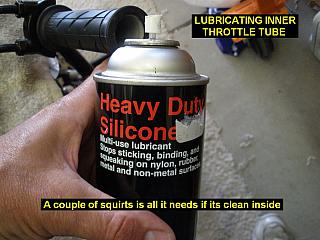

Before installing the right

bar, clean out the throttle tube if needed and put the throttle tube/cable assembly on first, then slide it up the bar as needed to allow you to

slip the sleeve onto the fork leg.

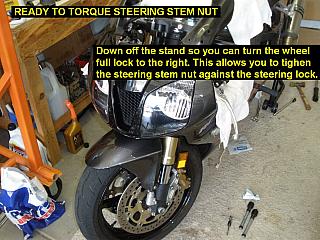

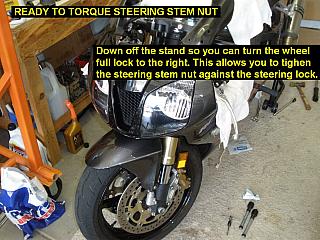

14) Reinstall the top triple clamp:

- Put cloth protection down on the top triple clamp

then gently tap it down evenly onto the fork legs and stem until it

bottoms. Tap it down alternating one light tap left of the steering

stem-one light tap right side of steering stem....

- Install the stem nut and tighten it a little bit to

make sure it is in truly bottomed on the stem.

- Torque the two fork pinch bolts to 20 ft·lbs.

- Take the front end, down off the stand and rotate

the front wheel to full right steering lock.

- Torque the steering nut to the appropriate torque

value for your year of RC51:

2000 & 2001 = 76 ft·lbs, 2002 to 2006 = 101ft·lbs

- Note: Scotts Steering Damper nut shown in

pictures. Scotts says to torque their steering stem nut to factory

setting up to 85 Ft·Lbs, so 2002-2006 is set to that limit when using

their nut.

15) Position and snug the RC-Bars:

- Download, print and cut out the RC-Bars Adjustment

Sight Gage templates:

LEFT TEMPLATE RIGHT

TEMPLATE.

The templates are used to set the angle between the bar, fork tube and steering

stem. It may help to glue or tape it to something rigid like cardboard.

- Slide each handlebar up until it touches the bottom

of the triple clamp, set it roughly at the correct angle and snug up the

pinch bolts equally and a little each at a time so that the bar can

still be adjusted if pushed with some force.

- Adjust the angle of each bar as shown in the

pictures. Do not wear glasses that distort angles as you move your head

viewing angle. Just use your eyeballs alone. Try to hold the template on

a parallel plane to the top of the triple clamp, then sight down the

center of the fork cap, steering stem and the handle bar.

- Adjust the bar so it is parallel with the edge of

the template when the other edge of the template is held directly over

the center of the fork cap and center of the steering stem.

- Use the other template to do the throttle side.

Obviously the throttle tube will make this job a little more difficult,

but with practice and measuring many times back and forth left/right you

can get the bars set at the proper and equal angles.

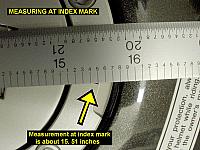

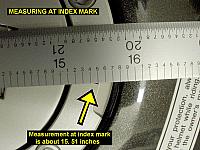

| Optionally - you can tram the bars using a

flexible steel rule or something similar. First put a tiny mark on the

center aft of the gas cap ring with a sharpie pen. Tram the front wheel

to a position of exact straightness by measuring the distance from each

fork cap to the index mark. Adjust the wheel position until you get the

measurements exactly equal. Pick a reference mark on the ends of the

bars, for example the closest edge of the screw in the middle of the

damper weight, and compare measurements to the index mark. Assuming the

measurements are not equal, adjust one of the bars a little. Assume you

knocked the wheel out of center doing this, and re-tram the front wheel

straight again before re-measuring the bars. Repeat as needed until you

get them equal to your satisfaction.

When I did this I found that using

the templates I had placed the bars within 0.05 inch of each other,

certainly well within reasonable tolerance.

|

- When you are happy with their position, snug the

pinch bolts equally and a little each at a time, enough so the bars will

not move when steering from lock to lock. We will torque them to the

final setting later, when we verify that everything fits, works together

and steers from lock to lock without interference.

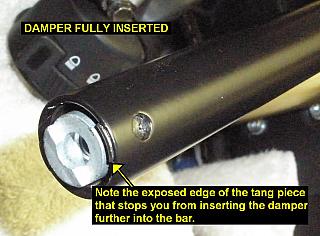

16) Install the dampers into the bars - Screw the weights on

to the dampers, they don't have to be tight. Align the tangs of the with the two

holes in the end of the bars. Push them in until they are stopped at the end of

the bar by the raised edge of the tang piece. You'll have to slide the

throttle up the bar a little to see the holes in the end, but afterwards you can

tighten the weight. Take off the weight on the left side after installing the

damper, because you still need to put the grip back on.

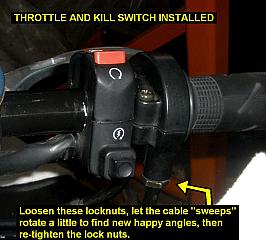

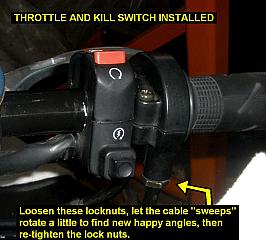

17) Install the the throttle housing, aligning the pin into the hole in the bar. Both screws are equal length. Tighten them up.

Install the kill switch aligning the pin in the bottom half into the hole in the

bar. The longer screw goes in the aft hole. Tighten it up. Depending on your

screwdriver collection you might find it easier to install the kill switch first

that way you can push the throttle cables out of the way so you can tighten that

front kill switch screw. Since the throttle is in a different location than it

used to be, loosen the two locknuts and readjust the the two throttle cable

"sweeps" that

enter the throttle housing. The angles won't change much, but they will each

find a new neutral "happy" position, then tighten the lock nuts again.

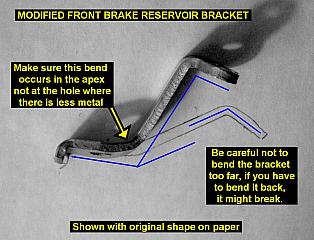

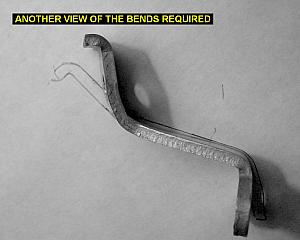

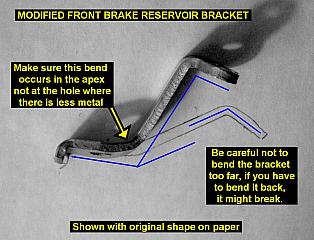

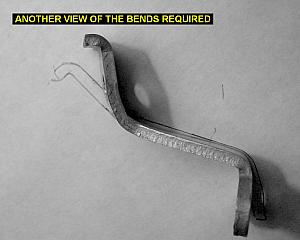

18) Remove the little aluminum bracket holding the front

brake master reservoir. CAREFULLY bend it as shown in the picture. Print out the

picture and set the bracket on the picture as you go along to help you get the

angles right. Try not to bend it too far, because it may break if you try to

bend it back and forth too much.

19) Install the modified bracket on the master cylinder, then

install the front brake lever assembly on the bar in your favorite location, but

don't tighten it up all the way yet. You may decide to move it once you get the

clutch lever in position and start testing steering lock. Keep in mind that some

locations may require a little more bending/modification to the reservoir bracket.

Caution: To avoid scratching the finish, loosen the brake/clutch controls adequately before rotating or sliding them on the bars!

20) Install the left grip and bar end weight. Overhang the

grip so it looks similar to the throttle side, with the same amount of bar

weight sticking out.

21) Install the Hi/Lo Beam/Turn Signal housing, aligning

its pin into the hole in the bar. The screws are equal length.

22) Install the clutch perch/lever assembly. Because of

differences in design from the front brake perch, the clutch bar clamp will most likely end up as

close to the fork tube as you can put it.

23) Sit on the bike and adjust the position of the brake and

clutch controls, then tighten them up.

24) Remove all the towels etc so you can observe the

moving cables and hoses as you steer left to right and right to left, full

lock. If you've got the bars where they should be and all the adjustments

talked about above done, you should not have any cable or hose problems, and

nothing hits the fairing or gas tank although they get close. Use the template again and verify that the bars are

equal angles. Sit on the bike and see if the bars look and feel to be at the

same angle. See pictures below

for clearances at full lock:

25) Tighten the bars to 96 in-lbs: Use the small torque wrench

with a 5mm allen wrench socket as follows:

- Using Loc-Tite is not recommended because a tiny

amount of anti-sieze has been applied to the pinch bolt threads to

prevent galling of the stainless steel bolts.

- Start out by torquing them both to 90

in-lbs then finish at 96in-lbs.

- Torque them equally in alternating increments so

the load placed upon them stays somewhat equal as they both get tighter.

- Apply smooth slow pressure to the wrench to ensure

accurate indication of the wrench.

- Since one bolt tightening will release tension on

the other bolt, check final torque on each bolt in alternating

increments over and over - until both bolts stop moving and will not

tighten further without exceeding 96 in-lbs

set into the wrench.

- Over-tightening hardware is just as bad as

under-tightening.

- Use of Torque-Seal or tiny dabs of paint on the

pinch bolts is a good way to visually see they have not loosened over

time. Otherwise you should periodically check them with the torque

wrench.

26) Install your fairing stay, windshield and mirrors then take it out for a test ride!

Have fun and ride safe!